Maintaining correct mold temperature is crucial for high quality end product in plastic processing. Our Swiss products can great control mould temperature, it has precise and reliable.

Maintaining correct mold temperature is crucial for high quality end product in plastic processing. Our Swiss products can great control mould temperature, it has precise and reliable.

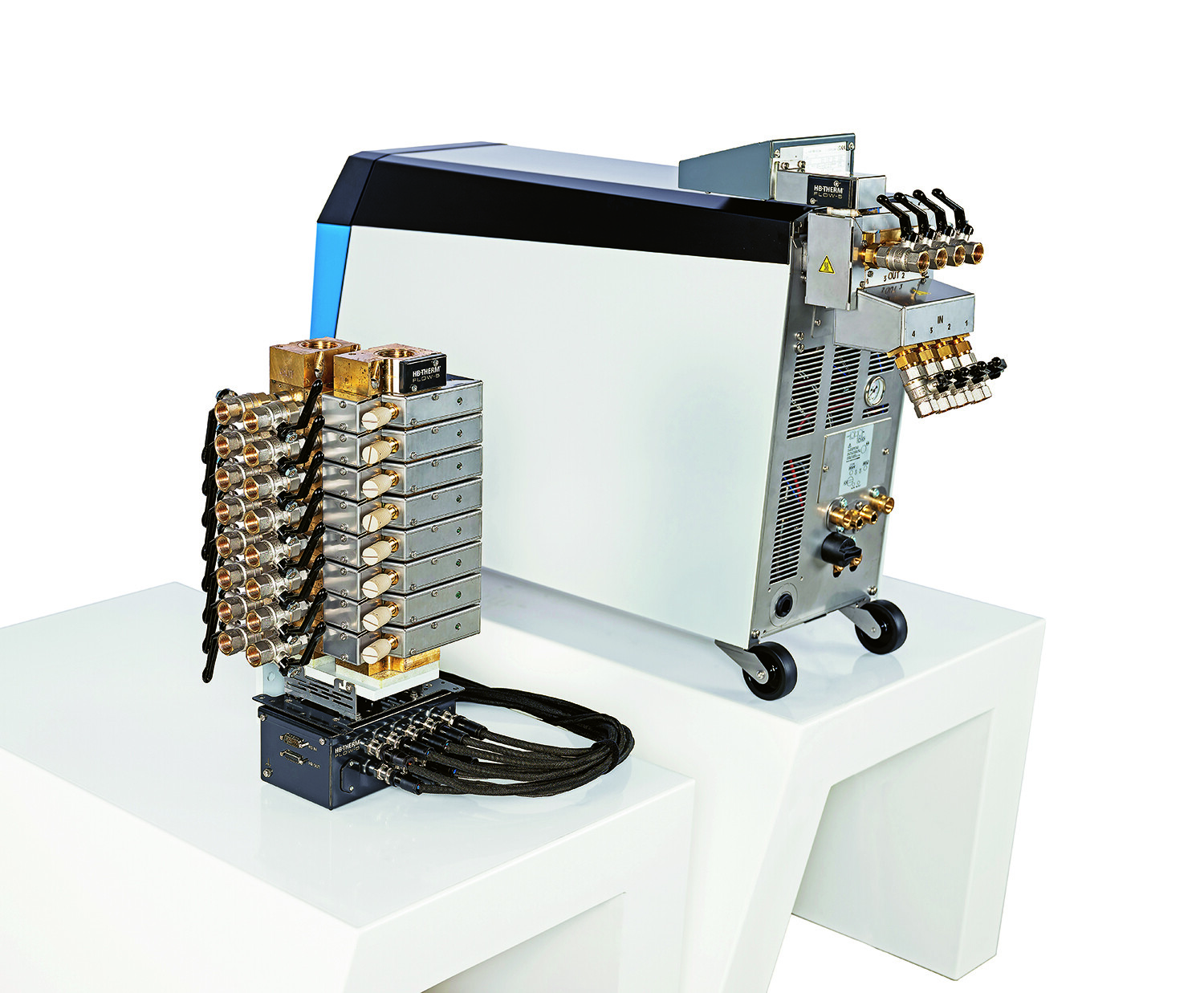

The technology of the Thermo-6 temperature control units is based on the highly successful Thermo-5. With over 100,000 units in use, HB-Therm has established itself as a global market leader. The unit’s technology is consistently focused on quality and durability. HB-Therm is the only manufacturer to support this with a lifetime guarantee on key components such as the heater – and now also on the flow meter. “Just better” represents the consistent advancement of their technology.

– Unique Warranty Promise: The Thermo-6 units offer a lifetime warranty on the heater and the ultrasonic flow meter, showcasing HB-Therm’s commitment to durability and innovation.

– Built-in energy efficiency: The integration of a speed-controlled pump and the Energy Control Assistant leads to a reduction in power consumption of up to 85 %. The versatile single unit solution is suitable for both small and large moulds and sets new standards in terms of efficiency with the new ‘Direct Drive’ pump.

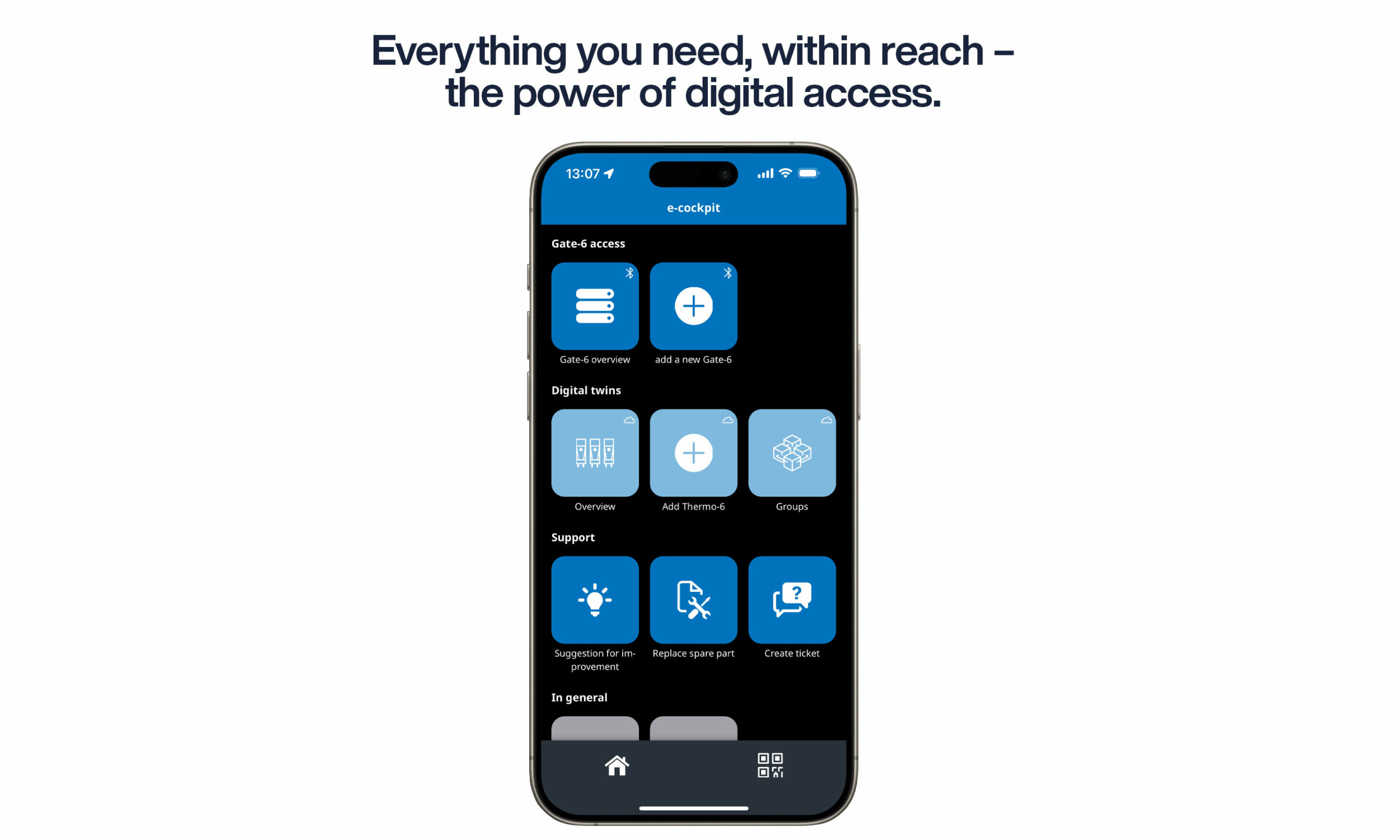

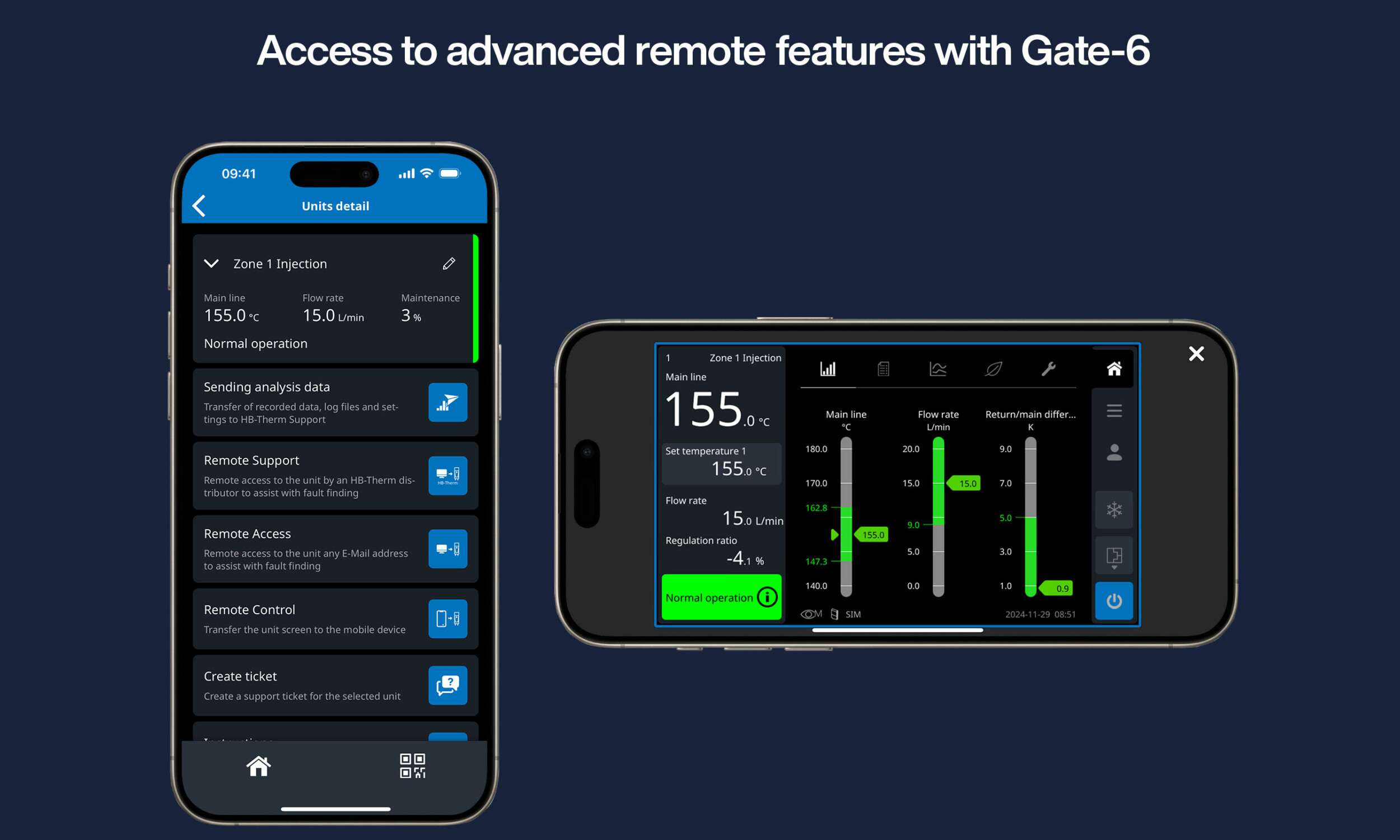

– Intelligent Networking: The Gate-6 interface server and e-cockpit mobile app enable Thermo-6 digital solutions such as cloud access, maintenance tracking and real-time remote support, enhancing connectivity and service.

– Extensive Standard Equipment: The Thermo-6 is equipped with a wide range of standard features, including an OPC UA interface, a frequency controlled pump and its status monitoring, software wizards, ultrasonic flow rate measurement, an expert system and several safety features that position it as a pioneer in the industry.

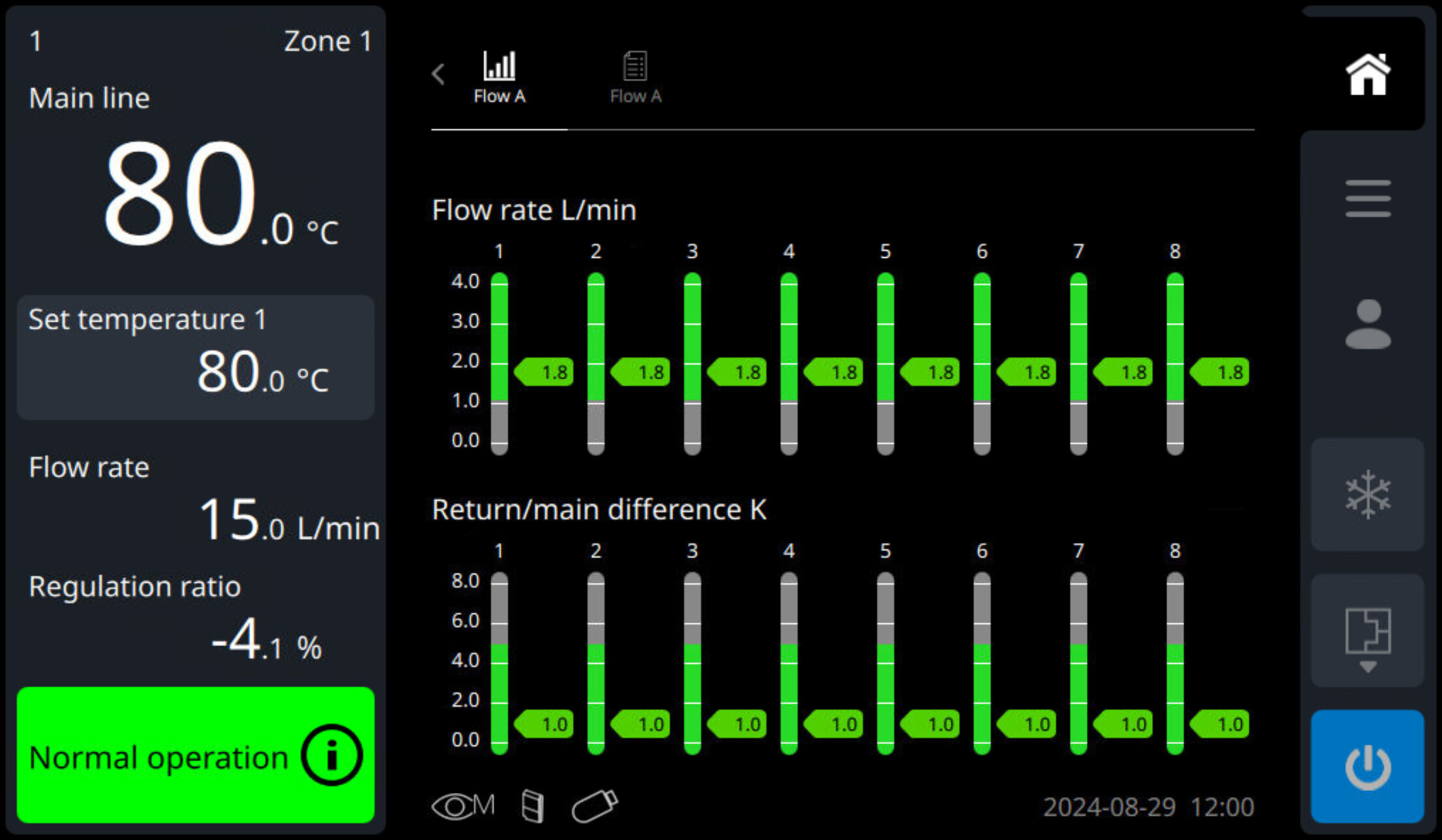

– Enhanced Control: The new 7-inch touchscreen simplifies operation with intuitive navigation, local process data recording and a preventive maintenance interval display in 28 languages.

– Low Maintenance: Overall, the Thermo-6 requires significantly less maintenance and is more user-friendly. The speed-controlled pumps not only save energy, but also reduce the overall maintenance effort and thus increase the service life.

The Thermo-6 temperature control units are equipped with an Ethernet interface as standard and communicate with the injection moulding machine or other further systems via OPC UA.

The interface server Gate-6 is capable of translating Euromap 82.1 into various proprietary machine protocols. These are:

– Interface DIGITAL (ZD)

– Interface CAN (ZC)

– Interface PROFIBUS-DP (ZP)

The use of a Gate-6 interface server brings completely new possibilities and advantages for the user. The smartphone app ‘e-cockpit’ sends analysis data to HB-Therm Service at the touch of a button and enables remote access to a unit by an HB-Therm specialist.

– Gateway to the digital world: Gate-6 and ‘e-cockpit’ is the concrete answer to today’s needs and future challenges in the digitalisation of temperature control technology.

– Control from anywhere: Work even more efficiently and safely with e-cockpit, from anywhere and from any unit.

– Everything at a glance: Clear and informative compilation of all important data and documents of the connected Gate-6 and the Thermo-6 temperature control units connected to it.

– Data security: The highest security standards guarantee data protection and security. Remote access or uploading of analysis data only takes place after explicit authorisation.

Classical ways of thermostating an injection mould cannot cope with all the challenges that arise during injection moulding. The best solution in this case is to regulate different temperatures simultaneously: high temperature during injection, low temperature during the cooling phase.

Equipped with two temperature control units, the Vario-5 is a variable-temperature control system using liquid heat transfer media. It alternately connects the high and low temperature units to the same circuit.

If the temperature control channels are properly set, the moulds used to date can be used. The Vario-5 is characterised by its ease of use and quiet operation. It assists the user in selecting the optimum settings.

Variable thermostatic applications

Performance

Improved temperature control

Lower heating and cooling energy requirements

Variable temperature system with standard thermostatic devices

Security

Fully automated process monitoring

Very accurate process management

Variable temperature system with standard thermostatic devices

Comfort

Easy to use

Convenient features

Quiet

Durability

Rugged construction

Improved mold protection

In circuits connected in parallel, changes in flow may not be detected as the fluid flow is distributed among the other channels.

Flow-5’s external flowmeters monitor parallel circuits individually and detect changes early enough so that production quality is not adversely affected.

Flow-5s are easy to use and provide ultrasonic measurements with high accuracy.

Advantages of circuits connected in parallel

Performance

Wide range of applications

Saves costs and energy

Security

Fully automated process monitoring

Comfort

Easy to use

Convenient features

Durability

Rugged construction

Improved mold protection

Everything at a glance

Ta strona używa plików cookie w celu usprawnienia i ułatwienia dostępu do serwisu. Dalsze korzystanie z tej witryny oznacza zgodę na używanie plików cookie. Czytaj więcej: polityka prywatności