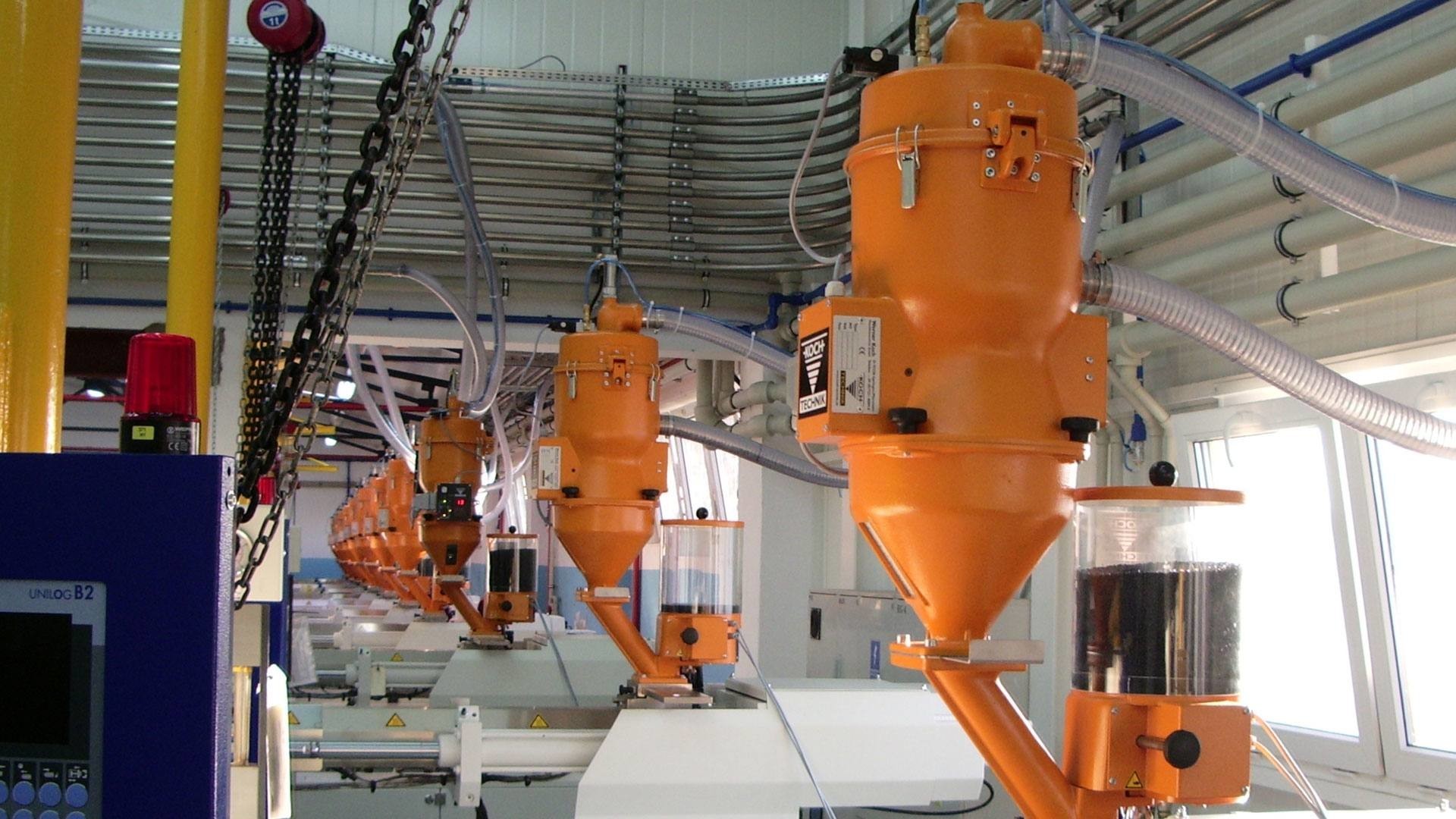

We plan, manufacture and install your central material supply system –

designed completely according to your wishes and adapted to your plastics processing.

We plan, manufacture and install your central material supply system –

designed completely according to your wishes and adapted to your plastics processing.

The visualization is monitoring and process management software for the central material supply system of your plastics processing.

The software is assembled and implemented in a modular way, completely according to your needs. The visualization communicates with your MES or ERP system via your network.

Visualization software over the central control cabinet

With the visualization, you can follow the path of the material in real time and adapt it flexibly. All production-relevant data are documented so that individual processes can be traced at any time.

The visualization gives you instant access to all components of your material supply system.

Calling up the individual stations brings you detailed information about the condition of your peripherals and the material to be processed.

Starting at the material input up to the processing machine, each station of the material is documented and archived.

The crucial point for the visualization is the central control of your material supply system. In the control unit, the data of all other control units are merged and forwarded to the visualization system.

PLC control: A touch panel supports the menu navigation

The central control unit based on SIEMENS PLC S7 is the brain of each fully automatic material supply system.

The material transport parameters can be entered and changed here via the touch display. All operating data are recorded, stored and can be printed out. Digital interfaces allow a data output as well as communication with external systems, e.g. with the KOCH visualization amd monitoring software.

Two safety filters protect the vacuum generator installed behind and filter out particles of up to 2 μm from the conveying air

The KOCH safety filter automatically cleans the dust-laden conveying air and thus protects the vacuum generators installed behind.

The body of the safety filter contains a replaceable polyester fleece cartridge filter with a filter surface of 2.5 m², which filters out particles of up to 2 μm from the conveying air of the material lines. An internal cleaning system cleans this filter cartridge after each conveying cycle in a split second. Therefore, no residual dust remains in the filter that can harm the vacuum generators connected behind it.

For conveying materials with a very high content of glass fibres, we offer a version with a filter housing made of special glass.

Ta strona używa plików cookie w celu usprawnienia i ułatwienia dostępu do serwisu. Dalsze korzystanie z tej witryny oznacza zgodę na używanie plików cookie. Czytaj więcej: polityka prywatności