In circuits connected in parallel, changes in flow may not be detected as the fluid flow is distributed among the other channels.

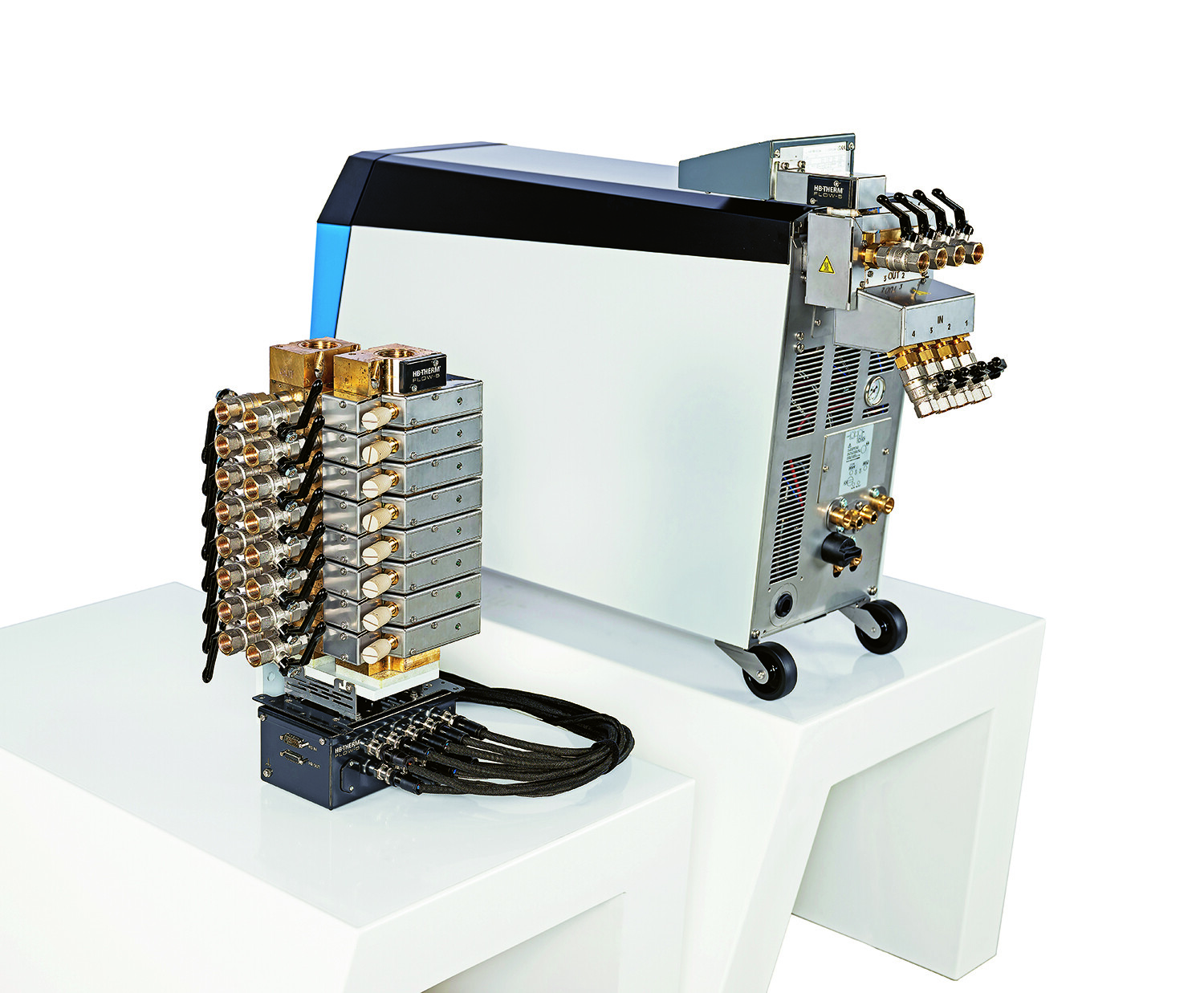

Flow-5’s external flowmeters monitor parallel circuits individually and detect changes early enough so that production quality is not adversely affected.

Flow-5s are easy to use and provide ultrasonic measurements with high accuracy.

Advantages of circuits connected in parallel

- greater overall flow ► faster temperature control

- smaller temperature difference between the main line and the return line

- better uniformity of temperature distribution

- fewer thermostat devices are needed (collecting identical temperature levels saves money and energy)

Performance

Wide range of applications

- smallest flow rates from 0.4 l/min

- high temperatures up to 200°C

- various configurations

Saves costs and energy

- fewer thermostatic devices are needed

Security

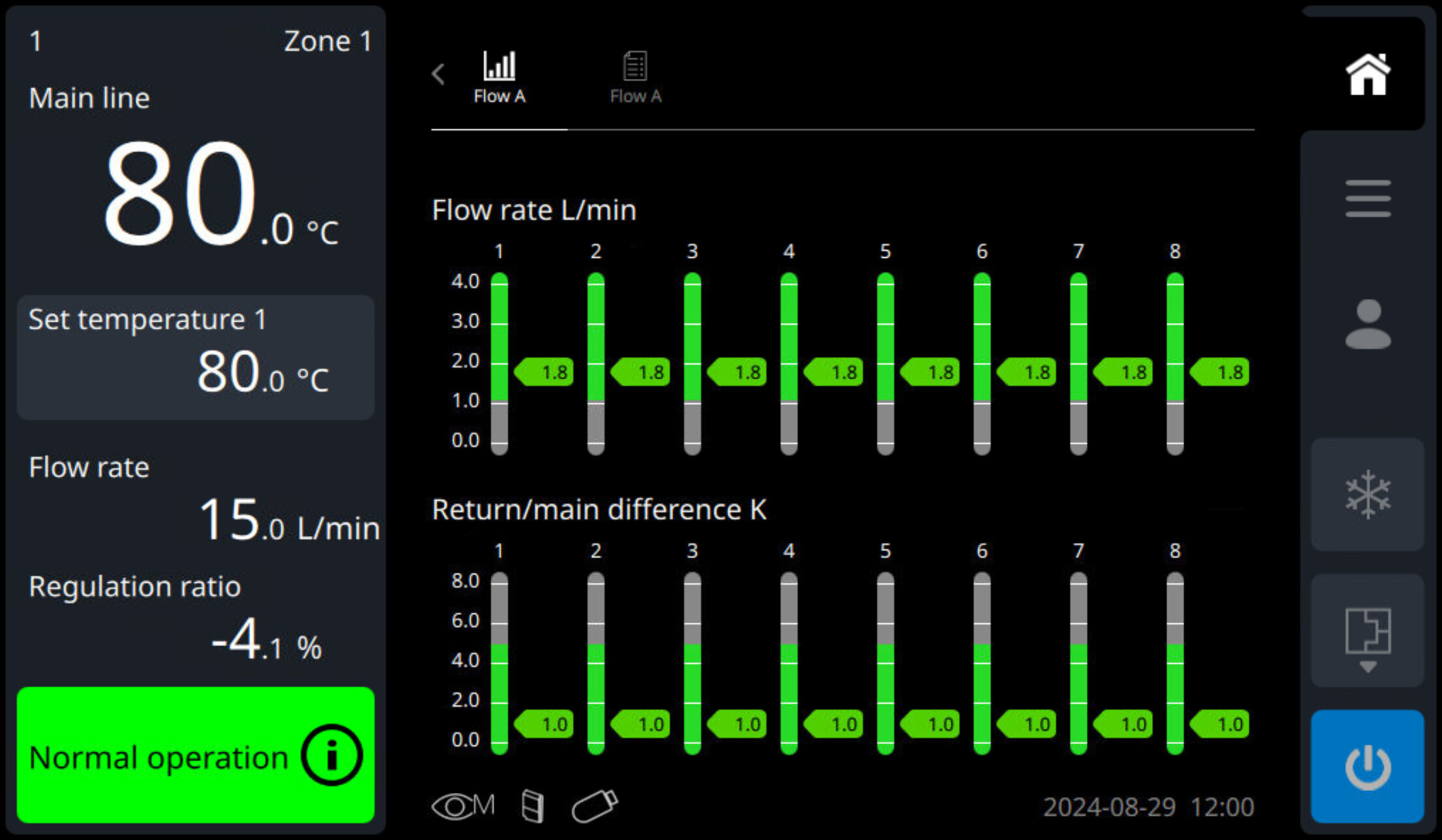

Fully automated process monitoring

- continuous monitoring of flow and temperature in each circuit

- highly accurate ultrasonic flow measurement

Comfort

Easy to use

- manual flow control assistant

Convenient features

- determination of procedural power per circuit

- automatic limit setting

- USB data logging and analysis in Excel

Durability

Rugged construction

- the hydraulic circuit uses only non-corrosive materials

- flow measurement without moving parts

Improved mold protection

- Early detection saves costly maintenance

Everything at a glance

- With a 7-inch touchscreen on the Thermo-6 series, the circuits are clearly displayed and fully automatically monitored in real time