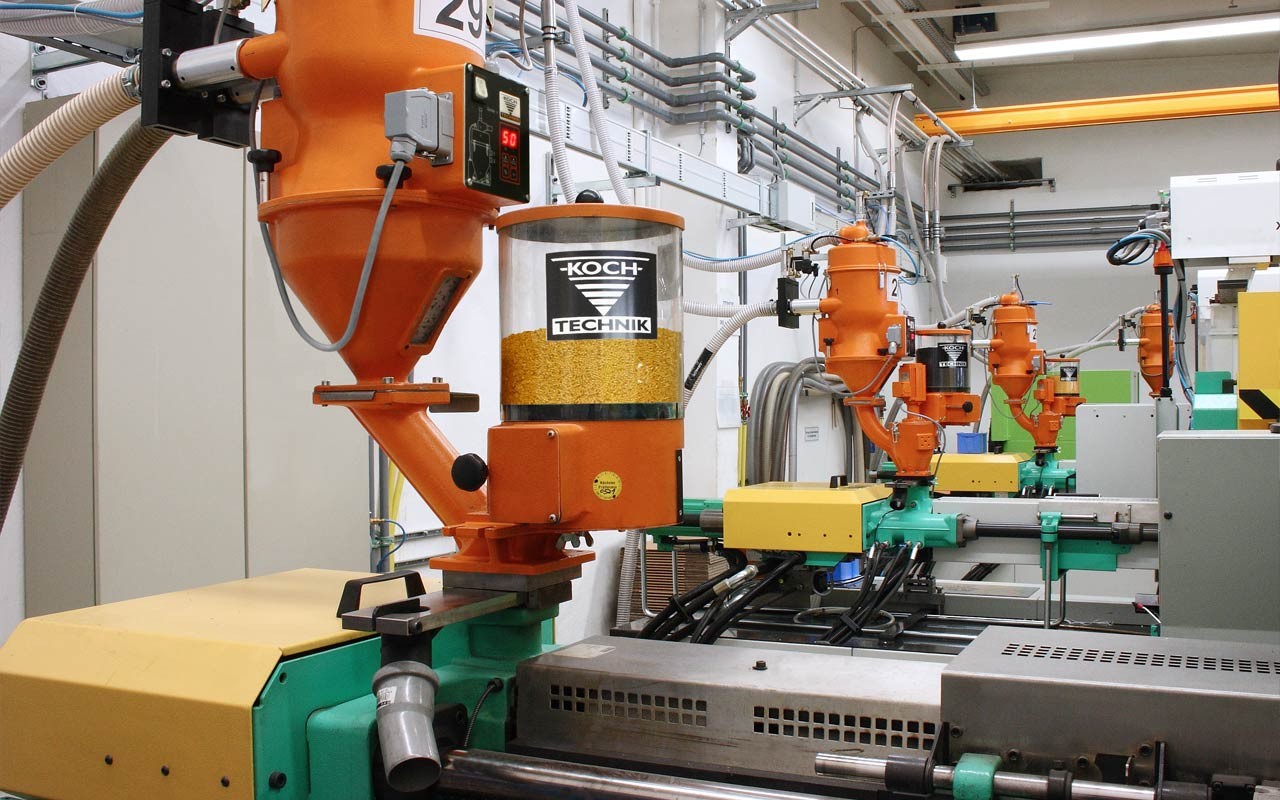

Jesteśmy specjalistami w dozowaniu, mieszaniu i barwieniu tworzyw sztucznych, zarówno w przypadku technologii wtrysku, jak i ekstruzji.

Jesteśmy specjalistami w dozowaniu, mieszaniu i barwieniu tworzyw sztucznych, zarówno w przypadku technologii wtrysku, jak i ekstruzji.

We provide you with flexible solutions for mixing and dosing plastics that make your company more economical.

Our pre-mixers mix plastics e.g. granulates, ground material or free-flowing powder with masterbatch or additives.

The homogeneous mixing is the basis for further processing – in injection moulding, extrusion or blow moulding.

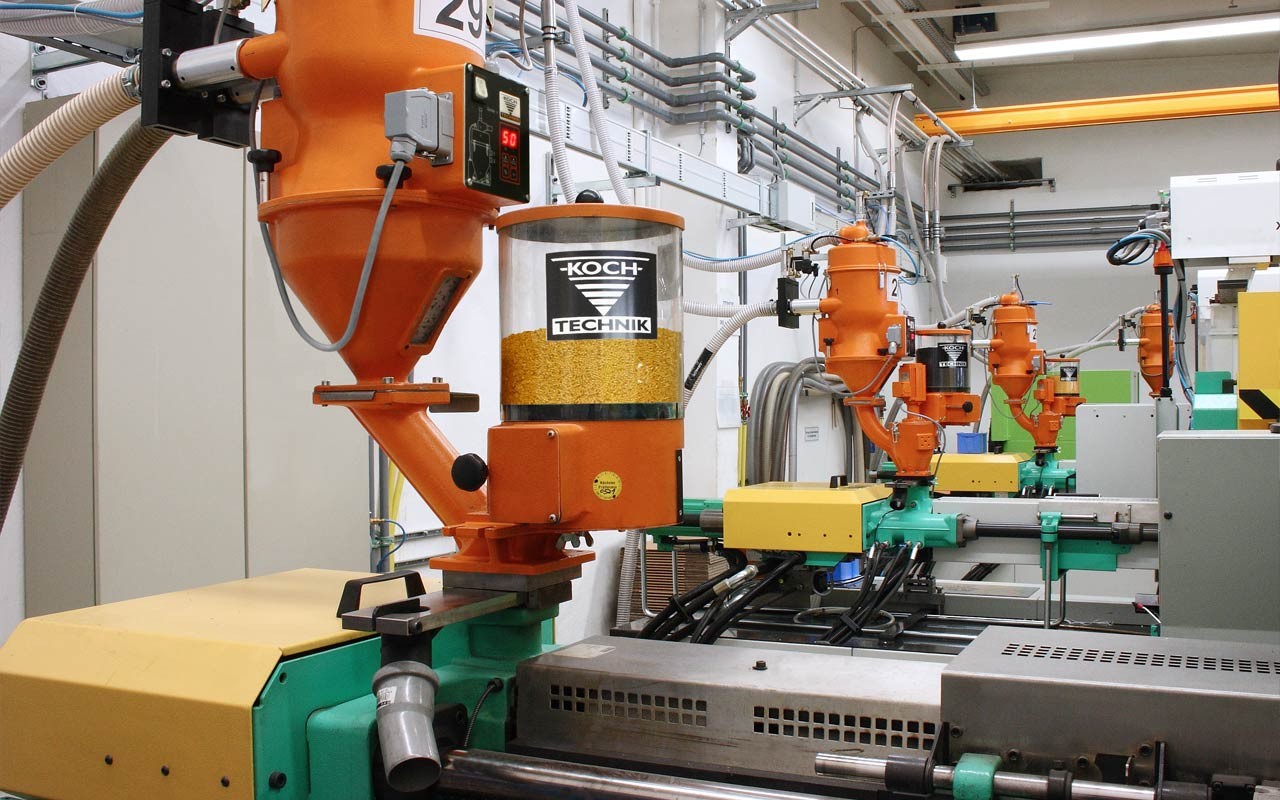

Pre-mixer on the injection moulding machine

for throughputs up to 25 kg/h and shot weights up to 0.2 kg

The KK mixer is almost ideal for mixing plastic materials with powder or masterbatch at smaller injection moulding machines.

The mixer has an inlet for the main material and an attachment for a dosing station.

| Throughput: | Mixer | type KK |

| with powder* and new material | max. | 20 kg/h |

| with masterbatch | max. | 25 kg/h |

| Shot weight | ||

| with powder* | max. | 150 g |

| with masterbatch | max. | 200 g |

* only well free-flowing powder

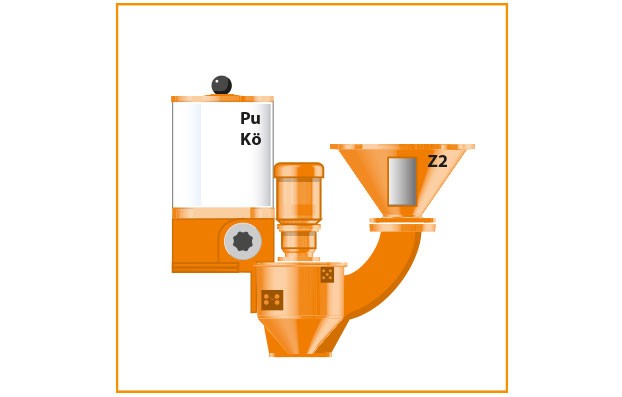

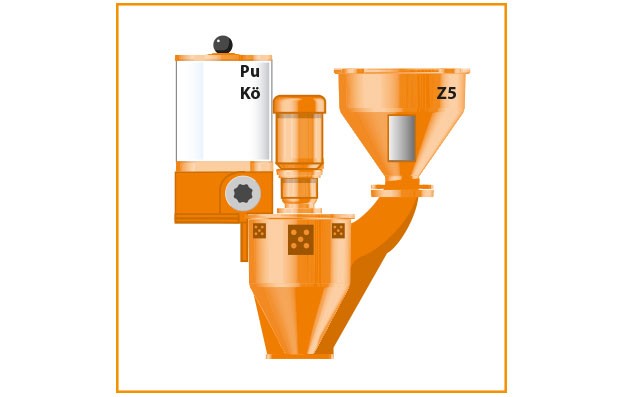

Pre-mixer on the injection moulding machine

ideal for throughputs up to 70 kg/h and shot weights up to 0.9 kg

The G mixer is the bigger brother of the KK mixer and has an attachment for the main material and two attachments for dosing stations. The plastic material and all dosed additive substances are homogenously mixed in the G mixer.

Up to four various material components, e.g. new material, regranulated material, masterbatch and additive can be processed.

| Throughput | Mieszalnica | type G |

| with powder* and new material | max. | 60 kg/h |

| with masterbatch | max. | 70 kg/h |

| Shot weight | ||

| with powder* | max. | 700 g |

| with masterbatch | max. | 900 g |

* only well free-flowing powder

Ta strona używa plików cookie w celu usprawnienia i ułatwienia dostępu do serwisu. Dalsze korzystanie z tej witryny oznacza zgodę na używanie plików cookie. Czytaj więcej: polityka prywatności